By embracing technology, companies like Abaxa are helping to increase productivity for businesses that rely on location services.

One tool that is essential in all of these industries is a Ground Penetrating Radar.

Digging up the earth can pose a multitude of health and safety risks. One small miscalculation can mean major problems and lengthy delays. With a ground radar scanning sub-surface material, you eliminate the risk of striking an underground pipe or utility cable and eliminate significant delays and budget blowouts.

So, if accurate sub-surface scanning technology exists, why do we still see news reports of these types of accidents on construction sites? It may be due to unskilled operators not knowing how a Ground Penetrating Radar works.

Let’s lift the lid on the GPR and find out how it works, and why it’s essential for your business.

Accurate and Non-Invasive

Relying on positioning records for sub-surface utilities is an outdated and dangerous method when excavating. Records can often be inaccurate, which results in health and safety hazards arising.

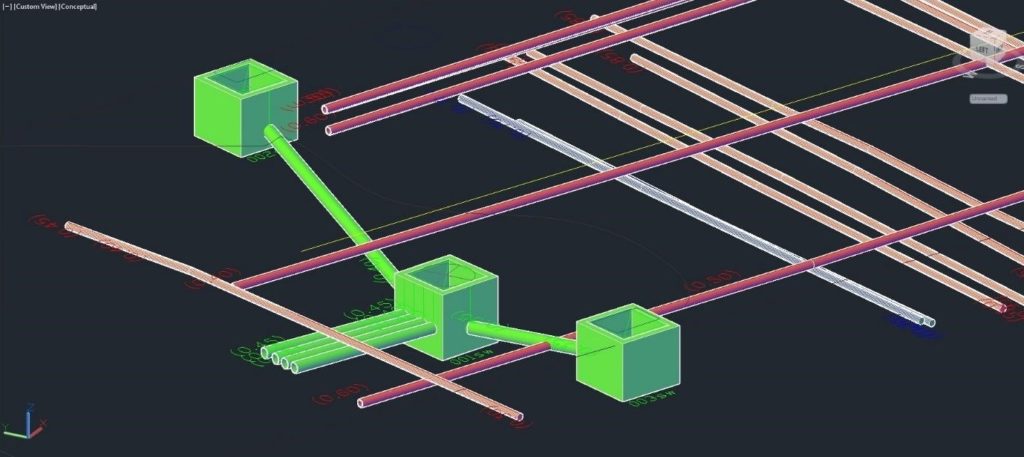

With Abaxa’s 3D Ground Penetrating Radar, you’re able to capture instant and accurate data of all materials up to eight metres under the surface – without any digging.

The radar has four multi-frequency antennae which survey and scan the subsurface and relay 3D images back to the unit. The 3D technology can capture material approximately two metres wide.

A GPR can be used on a variety of surfaces, including:

- Bitumen

- Concrete

- Sand

- Rock

- Limestone

The accuracy of the images is only matched by the speed at which the Ground Penetrating Radar can be operated. Using a skilled technician, large areas can be surveyed and cleared for excavation in a short amount of time.

It is essential that a skilled technician is used to operate the GPR. Not only will it save time in the long run, but you’ll also get accurate advice on depth penetration and survey design.

Safety-First Reduces Risk

Safety procedures around work sites are constantly under the spotlight. It’s essential to look at these procedures as timesaving rather than time-sapping. Anyone who has experienced a major incident on a work or mining site will know how lengthy the delays can be when a site is shut down.. Thinking safety-first is the right option.

The Ground Penetrating Radar is a clear safety-first solution for worksites. By gathering accurate data you’ll know the exact location of any underground utilities in the area. The refined management system that is used by Abaxa provides a thorough geological and climatic report.

The accuracy and speed at which the Ground Penetrating Radar can relay images means on-site operations progress on schedule.

Advantages and Applications

The advantages of Abaxa’s Ground Penetrating Radar are enormous. Along with the long list of safety benefits, it also offers:

- Highest quality sub-surface detection

- Automatic target detection recognition

- Automatic transfer of pipes and cables to CAD or GIS maps

- Optimised 2D and 3D tomography

While a GPR is predominantly used to locate underground utilities, it can also be used to:

- Assess pavement thickness

- Accurately predict bedrock depth

- Detect groundwater

- Detect gravesites

Qualified Operators

Using a Ground Penetrating Radar without a trained operator can be a dangerous and time-consuming experience. It’s vital that you have someone who knows how to accurately analyse the data and relay it quickly to the rest of the on-site team.

Abaxa employs a team of skilled operators that can perform an accurate sub-surface investigation. This will keep your project running efficiently and on time.

For over 30 years, Abaxa has been providing sub-surface detection to ensure safety and improved productivity on worksites around Western Australia.

You can read more about Abaxa’s Ground Penetrating Radar here. If you have more questions about our services, get in touch with us today.